we worked on the toe kicks for the sink side cabinets. they were a bit tricky.

for the cabinet nearest the porch door, dad figured out that we could clip a little piece of the toe kick going sideways on the cabinets leg NEXT to this cabinet, and then cut the toe kick piece to butt up right against that. otherwise there would have been a gap between the toe kick under this cabinet and the back panel on the cabinet next to it. so we got that one in.

that short little piece on the inner corner under the cabinet is the one we had to find a way to secure. this is the before picture without it

looks good. still need to put the baseboard trim back on the right end.

then we worked on how to do the inside of the peninsula. because of the corner cabinet facing the dining room, the legs at the back of that cabinet did NOT line up with the legs on the front of the kitchen-facing peninsula cabinet. the toe kick would be at a funky angle.

so the piece wouldnt clip on right.

plus i had no more laminate flooring left, and there was a gap there if we snapped it to the legs as intended.

so dad screwed a 2x2 board into the subfloor right at the end of the laminate flooring, in front of the legs.

then we screwed the toekick to the 2x2 board. voila, gap in flooring covered, toe kick straight from left end to right end. win!

for the piece in front of the sink we just had to measure from that toe kick to the end of the sink cabinet and install that. easy peasy. if you look closely on under the peninsula cabinets (with the flashlight in it), you can see the screw we used to attach that toekick.

the dishwasher has a removable toekick panel and clearly states in the instructions NOT to cover it with any other toekick material. (or you block access to the plumbing and electrical and height/level adjustments). that toekick is black.

the last gap we had to work on was between the panel on the side of the dishwasher back to the dishwasher toekick.

same type of little front to back gap as with the corner cabinet by the porch door.

so we screwed a block of wood to the side of the bottom of the inner mounting board, and cut a piece of toekick that went from the panel back alongside the dishwasher to the back wall, and just sort of propped it in place. it works. and its not like anyone will ever kick that piece since its behind the panel and to the side of the dishwasher toekick.

thursday/yesterday i went to ikea and returned the 3 extra toekick pieces and 4 glass drawer sides that were extra. then i bought a new deeper 24" wide drawer and the deeper glass drawer sides for that. picked up a piece of bodkin fancier trim to try above the cabinets. i picked up a 30x5 drawer front i'd like to try over the stove since it'll have finished edges. it'll need to be cut shorter, but the ends will be finished, and no scratches. i also picked up another utrusta metal shelf divider thing for the cabinet over the fridge. and 2 trash can lids for the times when the garbage or recycles stink. the trash really stinks right now and isnt even half full so the lid is good. and when the lids are not needed i can stick them down between the two trash cans that are narrower at the bottom than the top.

i need to finish the trim between the cabinets and the ceiling, and i will be done with ikea stuff. there are extra of the trim pieces i'd previously chosen that would need to be returned before the 365 days are up end of october. and i seem to be moving a lot slower. i just want to finish that and not have to worry about returns or exchanges.

otherwise there is still the backsplash to be decided. and i have no clue what i want.

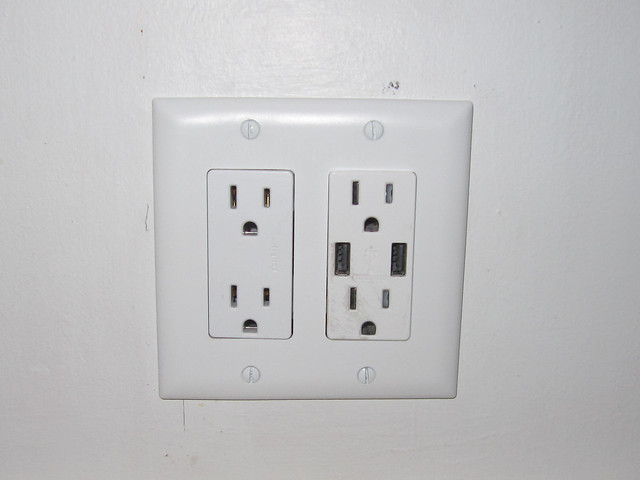

and there is one outlet i'd like to turn into a double outlet, which will require a new larger electrical box to fit two sets of outlets, and cutting into the sheetrock of the wall to remove the old box and install the new one. dad says we can do it. it'll require some sheetrock patching but i'm pretty good at that now and i have some leftover sheetrock.

then the kitchen will be done! its been 10 months. i dont at all mind how long its taken to get this far. i really really REALLY appreciated being able to do this at our own pace. to be able to take our time to solve problems we ran into rather than having to hurry thru and half-ass something. and it helped that we finished one half before we started on the other so i always at least had half a kitchen. and we managed to jury-rig up the old kitchen sink on top of the new cabinets until the new counters and new sink got installed. so i only had a few days of having to do dishes in the bathroom.